YTK32-400Ton Four Column Hydraulic Press Machine Deep Drawing Hydraulic Press

Description

Download

1.Use

Machine suitable for metal material’s stretching, stamping, bending, flanging, cold extruding, etc kinds of stamping process.

2.Feature

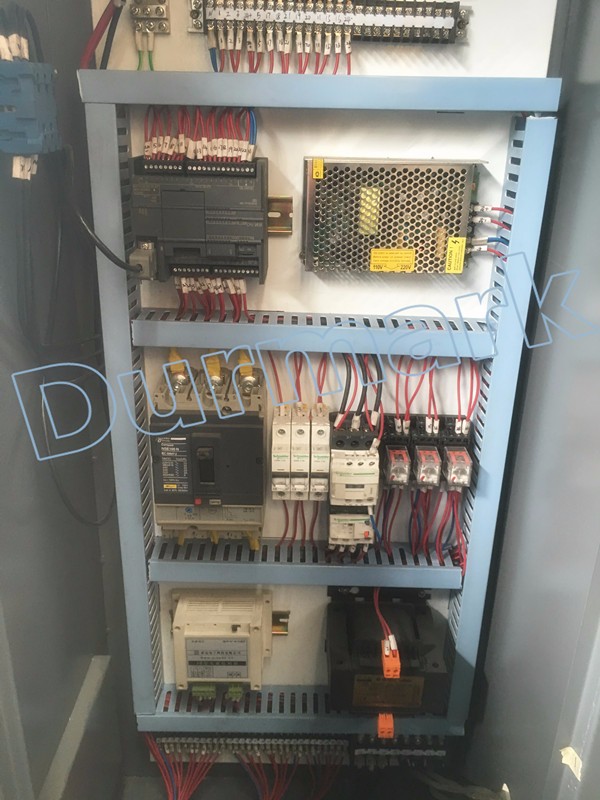

1.With independent motivation mechanism and electrical system, adopt relay/PLC(optional) control technology, button centralized control, equipped with movable button station. It can achieve jog and semi-automatic two operate way.

2.Machine’s working pressure, stroke range all can be adjusted according to process requirement. Stroke control adopts non-touch approach switch or select displacement sensor(optional).

3.Main construction

1.Machine adopts three beam four columns construction. Machine’s body contain: fixed worktable, slider beam, upper beam, hydraulic cushion, stretching plunger, columns, lock nut, adjusting screw nut. Beam adopts steel plate welding, After welding, inspection and aging treatment, eliminate the internal stress of the beam, which can ensure machine body rigidity and precision.

2. Machine has high rigidity and precision, machine body’s precision adjustment relies on adjusting column activity nut.

3.Slider movement relay on column and inside self-lubricating bearing guide to achieve up and down move.

4.Main cylinder and column adopts 45# steel forging quenching treatment.

Column and piston rod’s surface go through medium frequency hardening process to ensure the hardness arrive HRC45-52. Oil cylinder sealing adopt Japan NOK imported sealing.

This machine is applicable to all drawing, blanking, forming process, especially in the following areas:

all kinds of containers, all kinds of automobile covering parts, electric parts, kitchen utensils, tractor, motorcycle,

aerospace,aviation, electronics, instrumentation, plastic,rubber,chemical and other industrial departments.

1. Three beam four-column structures, after the computer optimized design, economic, and apply.

2. Hydraulic control system uses an integrated cartridge valve systems and reliability, long life.

3. Hydraulic shock is small, reduces piping and leak-point links.

4. Stand-alone electrical control system which is reliable, intuitive motion, easy for maintenance.

5. Centralized control design, two kinds of mode of operation for choose.

6. Setting process can be realized easily.

7. Working pressure, stroke according to the technical needs within the limits prescribed adjustable.