Products

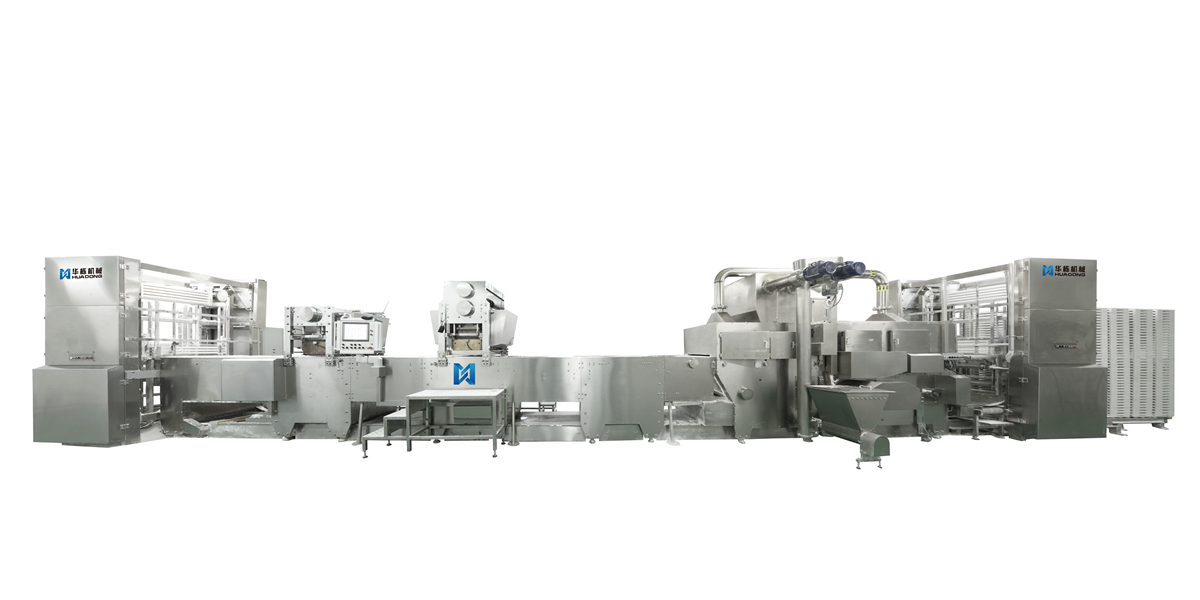

STARCH SOFT CANDY PRODUCTION LINE ( MOGUL )

starch mogul,sweets machine,soft candy machine

Description

DISCRIPTION

This production line is used to produce all starch-moulded products

such as jelly and gum (on pectin basis, gum arabic, gelatine, agaragar,

carrageenan).

It includes four parts machine:

1 . sugar cooking machine;

2 . depositor;

3 . powder processing and powder recycle machine;

4 . conveyer.

The candy shape can be selected by customer through our professional design.

SPECIFICATION

Production capacity: 8000-20000 kg / 8 hours (depending on the shape of the production of candy)

Power consumption: Power Specifications: 380v 50hz

Pouring line: 40kw

Powder handling: 85kw

Other auxiliary equipment: 11kw

Cooking system: 51kw

Steam volume: (steam pressure greater than 0.8MPa)

Water consumption: Depending on the production situation

Compress you: 7-8M3 / min (Compressed air pressure 0.6MPa)

2-4oC cold water: 0.35M3 / min

Equipment working environment temperature 22-25oC, humidity less than 55%

DEPOSITOR(OPTIONAL)

SM-II 6000

Tracking depositor: using regular electric driven, the whole depositor swing back and forth to keep same step with starch tray. it has 240 pistons (6 rows * 40 pistons / row) and deposit three times for each starch tray.

SM-II 8000

Full tray depositor: using regular electric driven, fixed depositor, starch tray pause when depositing. it has 720 pistons (18 rows * 40 pistons / row) and deposit one-shot for each starch tray

SMD-II 8000

Servo one shot depositor: using servo driven, same depositing method and same qty of pistons as sm-ⅱ8000. depositing finished one-shot with center filling.

STARCH CONDITIONING SYSTEM (HEATING AND COOLING)

This machine includes two systems: heat dryer system and cooling system. heat dryer system can control the wetness of starch below 7% and cooling system can effectively reduce the starch temperature

below 32℃. through heat dryer system and cooling system can realize starch completely processing and recycling.

KITCHEN SYSTEM

Sugar liquor(white granulated sugar,syrup) is fully dissolved in sugar dissolver.after fully dissolved in gelatin dissolver according to different recipes,the gelatin liquor or starch is added into sugar dissolver.after a full mixture,the sugar liquor is pumped by cam pump into mixing pot to be completely blended with the gelatin liquor.later,the sugar liquor is pumped by campump into the snakelike heating tube at a fixed quantity,the froom of pipe coil infusion machine is heated to maintain internal steam pressure at 7-8kg,thus the materials inside the tube heated partially vaporize through heat exchange.the materials are then moved through the upper end of the snakelike tube into vacuum presserving kettle whose inner pressure intensity is 0.6-0.7bar .the negative pressure allows the materials to boil and vaporize so as to increase the sugar content by extracting moisture and bubbles.to improve transparency,and to reduce the destructive effect of high temperature on gelation,then,thesugar liquor is pumped by the cam pump into the compounding pot where is goes through the compounding process of color,aroma,tartness and is then poured into the molding pot.the whole consecutive vacuum sugar cook process only requires 4 minutes.

The consecutive vacuum condensed sugar cook system as following advantages:

1.within a limited heating space,the best sugar cook efficiency perunit time can be achieved with a production capacity of 1200-1500kg/h

2.through condensation, the time required for the materials to go throught the heating process is greatly reduced,thus effectively prrventing the production of invert sugar and desstructive effect on gelation

3.the compulsive heating process ensures excellent heat transfereffect

4.the consecutive vacuum sugar cook process enjoys a high degree of automation and stability.it can effectively control the temperature,density,vacuum,heated vapor pressure,processing speed and quantity of the materials

5.the boiled materials are light-colored and endowed with splendid transparency and smoothness

GUMMY FINISHING SYSTEM

A.forepart of conveyer: conveying and primary cleaning starch

B.posterior of conveyer: conveying and twice cleaning starch

C.candy wetting conveying: through steam wetting to make finished jelly candy convenient for sugar coating

D.sugar coater: coating sugar for finished jelly candy

E.oiler: oiling for finished jelly candy

Pump casting is made of glass hard copper alloy, wear-resisting and corrosion-resistant. its dimensional precision is ensured by digital control process center. there are many models to choose from, its diameter ranging from 9-20, with 720 pcs pistons, hole 192, and hole 160 in a line. there is also pump casting with filling, holes on it are arranged in a reasonable way, meeting customers’ demands for diversity

Molding is made according to customers’ requirements, and its arrangement is designed by engineers to yield the best effects. molding is die cast with copper alloy, with its surface sprayed with anti-sticking dope. molding is clean without clear moulage nor adhering powder. the molding frame is easy and convenient to be disassembled.

Share your thoughts

6

0

Read more

Your rating

*

Name *

Email *

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed