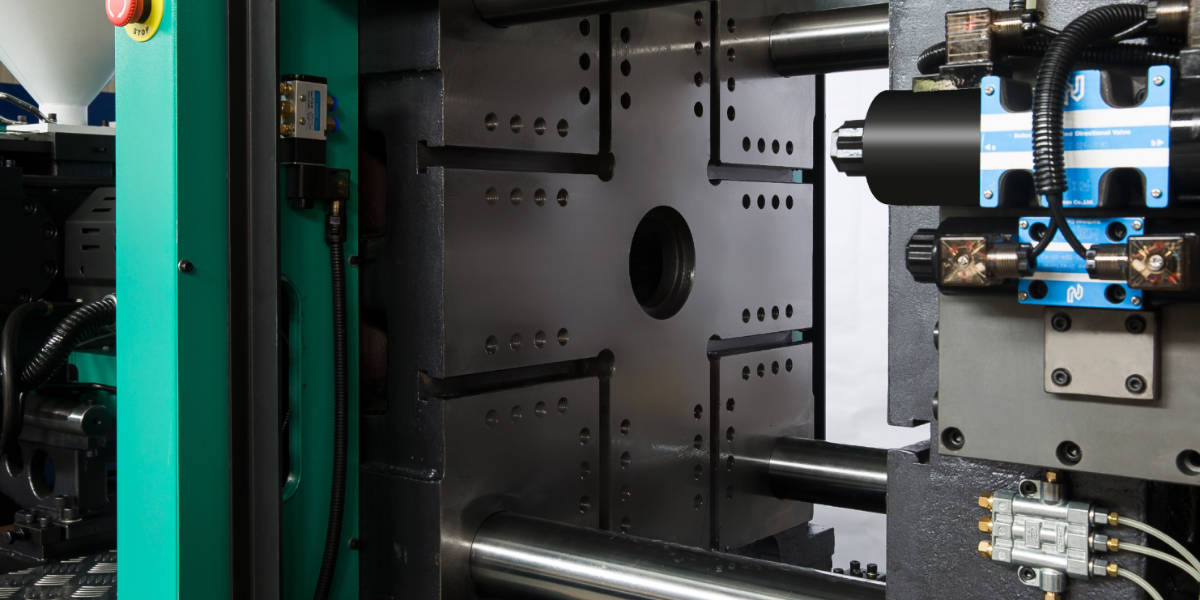

LOG-M6 130T Variable Pump Injection Molding Machine

Description

Specifications of LOG130

|

INJECTION |

LOG130 |

|||

|

A |

B |

C |

||

|

Shot volume |

cm³ |

215 |

263 |

302 |

|

Shot weight (ps) |

G |

196 |

239 |

274 |

|

oz |

7 |

8 |

10 |

|

|

Max injection rate |

cm³/s |

97 |

118 |

163 |

|

Screw diameter |

Mm |

38 |

42 |

45 |

|

Plasticizing rate |

Kg/h |

46 |

60 |

75 |

|

Injection pressure |

Mpa |

193 |

158 |

138 |

|

Screw L:D ratio |

|

22:1 |

20:1 |

18:1 |

|

screw speed |

r/min |

0~180 |

||

|

CLAMPING |

|

|

||

|

Clamping force |

Kn |

1300 |

||

|

Opening stroke |

Mm |

380 |

||

|

Platen size |

MmXmm |

610*610 |

||

|

Space between tie bars |

MmXmm |

410*410 |

||

|

Mold thickness (Min--Max) |

Mm |

150~430 |

||

|

Hydraulic ejection stroke |

Mm |

120 |

||

|

Hydraulic ejection force |

Kn |

42 |

||

|

POWER UNIT |

|

|||

|

Hydraulic system pressure |

Mpa |

17.5 |

||

|

Pump motor |

Kw |

11 |

||

|

Heating capacity |

Kw |

7.7 |

||

|

Number of temp control zones |

|

4+ (nozzle) |

||

|

GENERAL |

|

|||

|

Dry-cycle time |

sec |

1.3 |

||

|

oil tank capacity |

L |

200 |

||

|

Machine dimensions |

Mxmxm |

4.6*1.2*1.8 |

||

|

Machine weight |

kg |

3550 |

||

3.Unique third-platen flange design, when the third- platen deforms by the pressure, by the support of flange and tie bar. a reverse torque will minimizing the deform of the third-platen.

4. Adopting gear-adjusting ring with high-precision, large-scale transfer and compact structure to facilitate customer adjusting (the mold thickness in manual or automatic mode.

5.Steel bush in clamping unit adopts new structure, arrange rational holes of graphite to improve the effect of steel bush lubrication and the wear-resistance, reduces the usage of lubrication oil.·

|

|

|

|

|

|

|

Conjoined toggle |

High-hardness Platen |

Platen Flange |

Gear-adjusting ring | Graphite Bush |

1 .Injection unit adopts double-cylinder design, more higher injection pressure, more simpler structure and lower malfunction rate.

2. Enlarged-cylinder, adopting two-cylinder design, effectively prevent the adhesive- material leaking phenomenon caused by the machine vibration or other reasons while the nozzle is under high-speed operation.

3. Adopting graphite bush, improving the wear- resistance, reducing the frequency of using lubrication oil, effectively improve the cleanness of the injection part.

4.Injection cylinder adopts low-frictional seals, improving the response rate and improve the stability under the complicated processes of injection.

5.Bridge-style design, for different L/D ratio plasticizing parts.

|

|

|

|

|

|

| Sturdy Double-cylinder Injection | Balanced Double-cylinder Design | Graphite Bush | Low-frictional aeals | Moveable Bridge-style Rack |

1.Humanized computer interface operation,simple and convenient.

2.World famous computer brand professional for injection machine.

3.Data will be saved during production process,displayed by list,diagram and other forms to meet the practical requirements.

4.Huge storage and protect the data