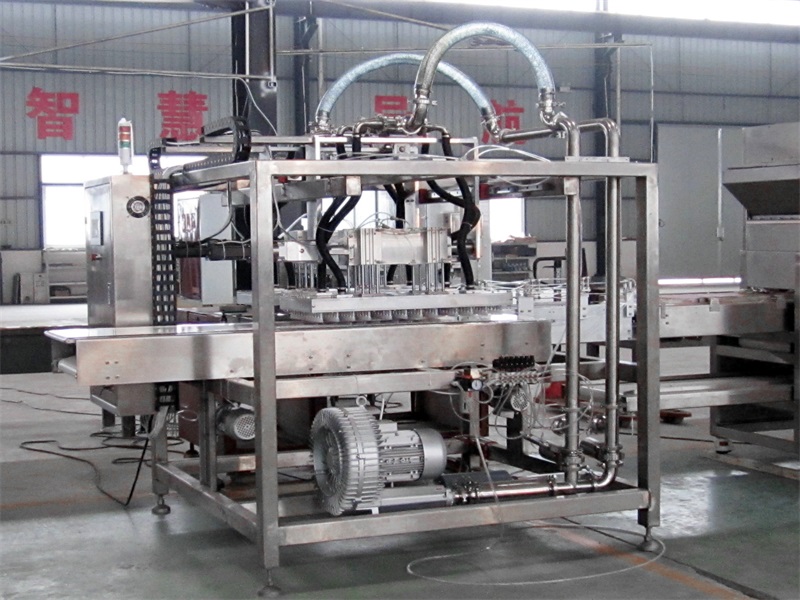

Large Demolding Machine

Description

Download

|

Chocolate Demolding & Pre-heating Machine Series |

|||||

|

A1 |

Heating Conveying Machine |

≤15 mould/min |

6.0 Kw |

120.0 Kg |

6m*1.1m*1.2m |

|

A2 |

Vacuum Demolding & |

≤10 mould/min |

9.0 Kw |

210.0 Kg |

3.6m*1.1m*1.8m |

|

A3 |

Rapping Demolding & |

≤10 mould/min |

9.0 Kw |

230.0 Kg |

3.6m*1.1m*1.8m |

|

A4 |

Multi-function Demolding Machine |

≤12 mould/min |

4.2 Kw |

350.0 Kg |

4.2m*1.5m*1.8m |

|

A5 |

Large Demolding Machine |

≤24 mould/min |

5.2 Kw |

420.0 Kg |

4.2m*3.8m*1.9m |

|

A6 |

Heating Tunnel |

≤15 mould/min |

5.3 Kw |

450.0 Kg |

2.2m*1.2m*2.4m |

|

A7 |

Small Heating Machine |

≤15 mould/min |

3.5 Kw |

120.0 Kg |

1.5m*1.1m*1.2m |

Equipment Overview

This large-scale demolding machine adopts the demolding mode of twisting and vacuum demolding, which makes 2D mold demolding speed doubled, and it is suitable for product demolding of production line of large capacity.

Equipment Description

■ Mode of demolding : By twisting and vacuum;

■ Demolding ability: 2D mold ≤1000kg/h;

■ Over turning and butt joining: These features provide to achieve the packaging of the product as per the direction;

■ Auto packaging: The product can be directly packed into box immediately after demolding , which is easy and cost saving;

■ Flexible parameter setting: The number and frequency of mold rapping, the distance and angle of the connection, the parameter setting of flexibility is more flexible to the demolding of different products;

■ PLC + servo control system: Electronic control system using the concept of integration and optimization makes the PLC and servo control more efficient and reliable;

■ Smart connection with the packing machine: Once the packaging machine breaks down, the device will automatically stop;