WC67K Hydraulic Press Brake Stainless Steel Press Brake

Description

Download

Product Description:

Machine using

The bending machine has high productivity and high working accuracy, using different shapes of the upper and lower mould, can be bent into various shapes artifacts, stroke at a time can be to a bending forming of sheet metal, after a lot of bending can obtain more complex in the shape of the workpiece, equipped with the corresponding equipment, can also make a punch.

Product appearance structure

1.Using UG (fem) analysis method, the computer aided optimum design, beautiful shape.

2.Machine adopts steel plate welded structure, with sufficient strength and rigidity, hydraulic transmission to ensure work is not due to variation in thickness of sheet metal or lower die "V" shaped groove improper selection and cause serious overload accident, in addition the machine working smoothly, with convenient operation, low noise, safe and reliable, etc.

3.Equipped with mechanical stop in the cylinder, ensure that the slider to the repetitive positioning accuracy of bottom dead center, to ensure the consistency of the bending Angle during mass production.

4.Using German technology to eliminate internal stress.

5.Overall framework using the way of sand derusting and spray with anticorrosive paint.

Work slider structure

1.This machine adopts hydraulic electric control, sliding block can be adjusted, and have some fixed, semi-automatic, automatic movements such as norm, using dynamic specification can easily test and adjustment.

2.Acting on the design of bending machine, double oil cylinder work at the same time, balance, convenient operation, safety.

3.In the dead center have confirmed when rolling function, to ensure that the workpiece precision.

4.Under the condition of the relevant national standards, bending Angle precision of plus or minus 45 '.(reference standard JB/T22572-1999.)

5.A slow decline control function, the operator can better control the workpiece.

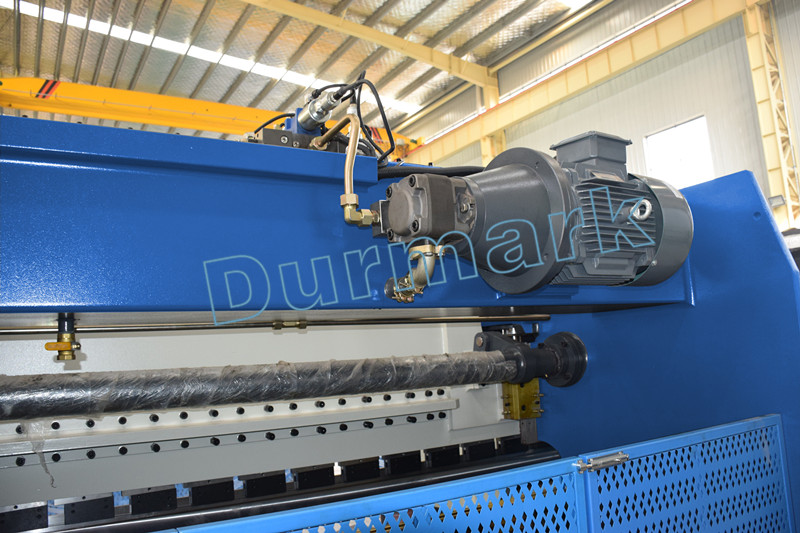

Hydraulic system

1. Hydraulic system can realize the slider falling fast, slow down, bending work speed, quick return and upward, downward slide block in the process of the abrupt stop such action.

2. The axial plunger pump, oil pump adopt can bear high pressure, low noise.

3. Choose Taiwan tripod base company seal, the sealing performance is good, reliable operation, long service life.

4. The machine can work continuously under the rated load, hydraulic system leak proof and sustained stability, high precision.

Electric control system

1. The electrical components and materials in accordance with international standards, safe and reliable, long life, strong anti-jamming capability.

2. Comes with removable foot switch operation.

3. Electronic components to choose high quality famous brand product.

4. The machine adopts ac 380 v three-phase four-wire system power supply and control circuit of ac 220 v voltage.

5. The motor main circuit with short circuit, overload, open phase protection.

6. Button on the action button installed on machine tools, electrical switches, indicator lights, installed on the electric control box.

7. Oil pump stop button as well as the total machine tool button, when the pump stop working, the whole machine stop working.

8. The machine is equipped with corresponding inching control button and stop button

Slider synchronous control

Bending machine stroke of synchronization, the use of mechanical hydraulic synchronous mechanism, simple structure, stable and reliable, with synchronous precision required for this machine, general need not often maintenance to maintain a long-term use.

Back-gauge

Back gauge adjustment by the 0.55 KW motor drive, after gear reduction by screw transmission. In the press the regulation according to the "+", "-" can be achieved when the adjustment of the baffle plate forward or backward, digital display size (location) in the regulation of motor regulation cannot achieve the required value, can be manually adjusted twisted round manual fine-tuning to ensure that the required value adjustment.

Mould

1.Random standard mold one set up and down.

2. The upper die adopt multiple segmental short die, stitching required length, has a high accuracy good interchangeability, easy tear open outfit.Connection part of the compensation mechanism, to compensate for the workbench when bending sheet metal and the deflection of slider, ensure the high working accuracy.

3. The lower die processing into different "V" shaped groove is convenient for the operator to choose, and is equipped with lower die roll over institutions simply put the lifting chain on the slider lug and the lower die lug, loosen the top slider template rose can turn the lower die choose "V" shaped groove position required to the surface.And is equipped with the deflection compensation structure.

Standard Equipment |

Safety Equipment (CE & NR12) |

|

|

1.Estun E21 NC control System

2.Powered Depth Y-axis & Back gauge X-axis

3.DELTA Inverter controlled back gauge

4.HIWIN Ball screws & Polished rod

5.Plate Support Arms

6.Bosch-Rexroth Hydraulic

7.Germany EMB Tubing connector

8.Siemens Main Motor

9.Telemecanique/Schneider Electrics

10.Hydraulic & Electrical overload protection

|

1.Safety Standards(2006/42/EC):

1)EN 12622:2009+A1:2013

2)EN ISO 12100:2010

3)EN 60204-1:2006+A1:2009

2.Front Safe Fence/Safenty Linght Curtain(Optional)

3.South Korea Kacon Foot Switch

4.Back metal safe fence

5.Safety relay with Monitor the pedal switch and safety pritectio

|