Products

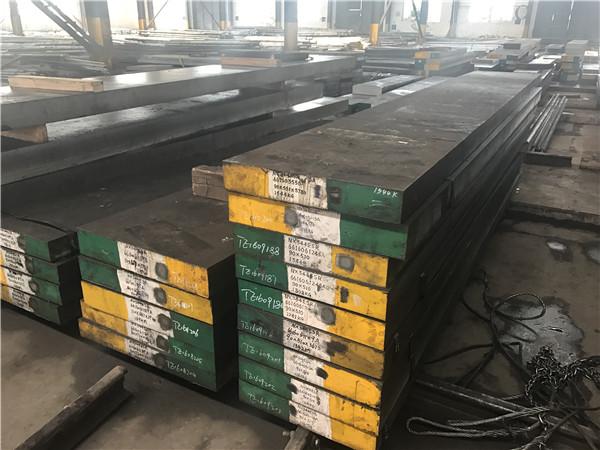

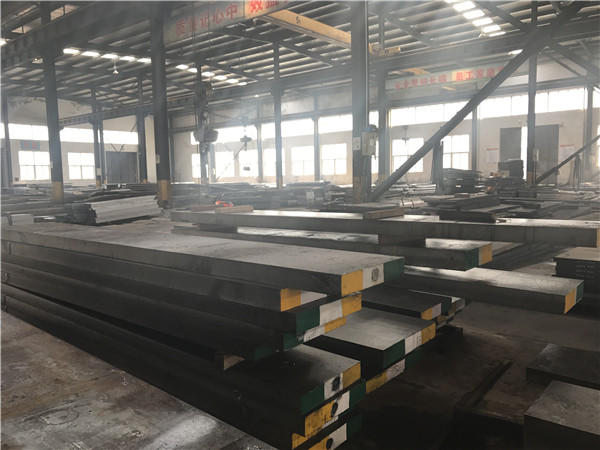

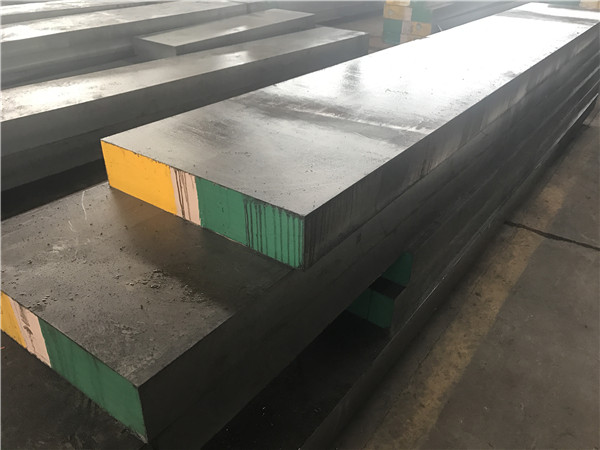

NX344 / 1.2344 ESR Forged Blocks for Plastic Mold

high quality

Description

NX344 / 1.2344 ESR Forged Blocks for Plastic Mold

NX344 is a special grade which is developed by our Ningshing Special-Steel.

It is high quality level of 1.2344 ESR, a kind of hot work tool steel.

At the beginning, we develop this grade for making plastic mold for high-grade of snack box because of its better performance on thermal resistance and good toughness that could improve to get a longer lifetime of the mould.

Chemical Composition (%)

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

0.36 |

0.90 |

0.30 |

≤ |

≤ |

5.00 |

1.25 |

0.90 |

Dimensions

|

Thickness (mm) |

Width (mm) |

Length (mm) |

|

100-500 |

100-910 |

3000-5800 |

Delivery Condition

EAF+LF+VD+(ESR), Forged, Spheroidizing Annealed, EFS, Hardness≤230HB, Machined surface,

UT 100% SEP1921 Class 3 E/e,

Spheroidized Microstructure as per standard NADCA207-2003 AS1-AS9

Impact test: Transverse impact test as per ASTM A370, V notch impact test (5 samples, size of 10 x 10 mm),

average value >=11 J (delete max. and min.), single value >=8 J

Forging Technique

|

Heat |

Start Forging |

Finish Forging |

Cooling Method |

|

1020-1150 °C |

1100-1120 °C |

900-850 °C |

Pit or Sand Cooling |

Heat Treatment

Annealing

750 to 800°C (1382 to 1472°F)

Slow controlled cooling in furnace at a rate of 10 to 20°C/hr (50 to 68°F/hr) down to approx. 600°C (1112°F), further cooling in air.

Hardness after annealing: max. 235 HB.

Stress relieving

600 to 650°C (1112 to 1202°F)

Slow cooling in furnace; intended to relieve stresses set up by extensive machining, or in complex shapes.

After through heating, hold in neutral atmosphere for 1 - 2 hours.

Hardening

1000 to 1040°C (1832 to 1904°F)

Oil, salt bath (500 - 550°C / 932-1022°F), air

Holding time after temperature equalization: 15 to 30 minutes.

Obtainable hardness:

52 - 56 HRC in oil or salt bath,

50 - 54 HRC in air.

Tempering

Slow heating to tempering temperature immediately after hardening / time in furnace 1 hour for each 20 mm of work piece thickness, but at least 2 hours / cooling in air. It is recommended to temper at least twice. A third tempering cycle for the purpose of stress relieving may be advantageous.

1st tempering approx. 30°C (86°F) above maximum secondary hardness.

2nd tempering to desired working hardness.

The tempering chart shows average tempered hardness values.

3rd for stress relieving at a temperature 30 - 50°C (86 to 122°F) be low highest tempering temperature.

Share your thoughts

6

0

Read more

Your rating

*

Name *

Email *

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Refill

People who viewed this item also viewed