NOS430 Die Steel for Hot Forging Toolings

Description

Download

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

0.38 |

0.15 |

0.40 |

≤ |

≤ |

Patented |

||

|

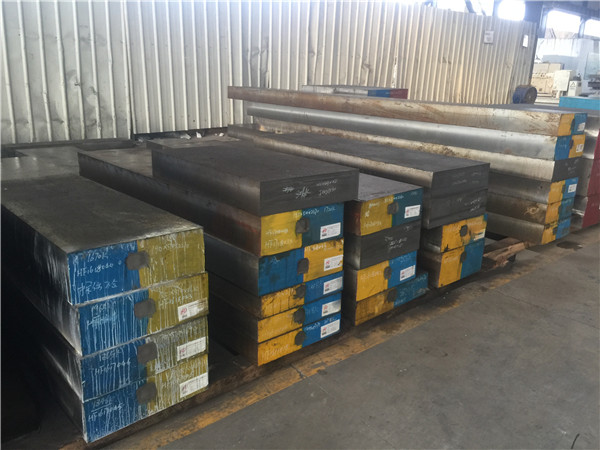

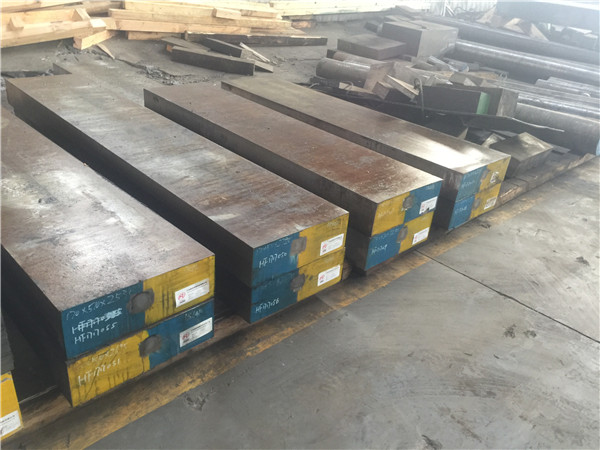

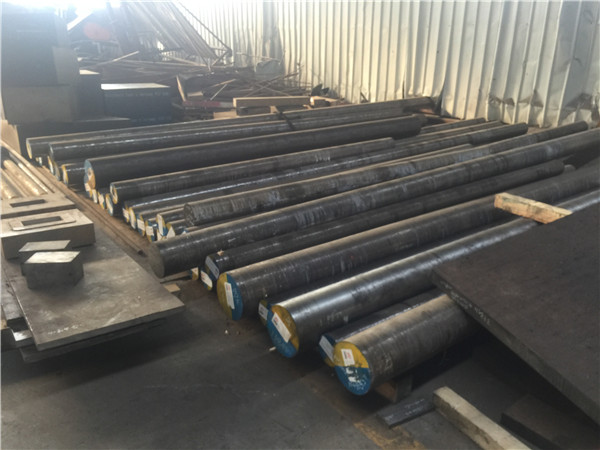

Shape |

Thick / Dia. (mm) |

Width (mm) |

|

Round |

100-500 |

/ |

|

Block |

100-400 |

200-1000 |

|

Temperature |

Density |

Elasticity Modulus |

Thermal Expansivity |

Thermal Conductivity |

|

20 |

7800 |

210000 |

-- |

-- |

|

400 |

7700 |

180000 |

12.6 |

33 |

|

600 |

7600 |

145000 |

13.2 |

33 |

|

Hardness |

Tensile Strength (Rm) |

Yield Strength (RP0.2) |

|

48 |

1620 |

1400 |

|

45 |

1470 |

1470 |

|

40 |

1250 |

1250 |

|

Thickness |

Time |

Thickness |

Time |

|

5 |

60 |

50 |

300 |

|

10 |

90 |

60 |

390 |

|

20 |

160 |

70 |

420 |

|

30 |

240 |

80 |

440 |

|

40 |

280 |

90 |

495 |

|

Industry |

Features |

Steel Grade Recommendation |

|

Die Casting |

Die Casting is a kind of metal casting technique. It is characterized by using the mould cavity to have high pressure on molten metal. It has the good performance in anti heat cracking, anti corrosion, anti-crack, red hardness. |

NOS411, |

|

Hot Extrusion |

Before extrusion, heat the metal over temperature of recrystallization. It has the good strength at high temperature, high ductility and good toughness, high thermal fatigue resistance and thermal wear resistance, as well as the anisotropic properties of consistency. |

NOS411, |

|

Hot Forging |

Hot forging is a kind of processing under the condition of over the temperature of recrystalization. It has the good thermal wear resistance, heat intensity, high ductility and good toughness, high thermal conductivity. |

NOS411, |

|

Hot Stamping |

Hot Stamping is the rapid molding in the mould blank and hardening heat. It has the good thermal conductivity, hot bending strength, high toughness and ductility. |

NOS411, |

|

Injection Molding |

Injection molding is a kind of forming process of injection and molding at the same time. It has the high polishability, good corrosion resistance, wear resistance, anti-cracking and thermal conductivity. |

NOS411, |

|

Compression Molding |

Compressing Molding is a process of solidifying the thermosetting plastics through heating and pressing. It is usually used for plastic molding with reinforced glass fiber. It has the good wear resistance, strength, hardness and corrosion resistance. |

NOS411, |

|

Blow Molding |

Blow Molding is a process blowing the raw materials in the closed mould to be the hollow products by gas pressure. It has the medium strength and wear resistance, good thermal conductivity and corrosion resistance. |

NOS411, |

|

Extrusion Molding |

Extrusion Molding is a kind of process making the heat plasticized materials to be a specific profile though extrusion. It has the medium strength, but high demand on corrosion resistance and wear resistance. Nitridation is generally used for the mould of fiber reinforced products. |

NOS411, |

|

|

AISI |

DIN |

JIS |

Stock |

Application |

|

Hot Work Tool Steel |

H11 |

1.2343 |

SKD6 |

√ |

Die Casting Dies,Extrusion Dies, Hammer Dies, |

|

H13 |

1.2344 |

SKD61 |

√ |

||

|

H10 |

1.2365 |

SKD7 |

|

||

|

—— |

1.2367 |

—— |

|

||

|

L6 |

1.2714 / 1.2713 |

SKT4 |

√ |

||

|

H12 |

1.2606 |

SKD62 |

|

||

|

H21 |

1.2581 |

SKD5 |

√ |

||

|

Cold Work Tool Steel |

D3 |

1.2080 |

SKD1 |

√ |

Cutting Tools, Punching Tools, Shear Bladers, Reamers, Thread Rolling Dies, Calipers, Sockets etc. |

|

—— |

1.2601 |

~SKD11 |

√ |

||

|

D2 |

1.2379 |

~SKD11 |

√ |

||

|

—— |

1.2379 MOD |

DC53 (Daido) |

√ |

||

|

D6 |

1.2436 |

—— |

|

||

|

O1 |

1.2510 |

SKS3 |

√ |

||

|

O2 |

1.2842 |

—— |

|

||

|

A2 |

1.2363 |

SKD12 |

|

||

|

S1 |

1.2550 |

—— |

|

||

|

S7 |

1.2357 |

—— |

|

||

|

—— |

1.2767 |

SKT6 |

|

||

|

L2 |

1.2210 |

—— |

|

||

|

Plastic |

P20 |

1.2311 |

—— |

√ |

Mold Base, Core & Cavity, Bumper Mold etc. |

|

P20+Ni |

1.2738 |

—— |

√ |

||

|

P20+S |

1.2312 |

—— |

√ |

||

|

—— |

1.2316 |

—— |

|

||

|

420 |

1.2083 |

SUS420J2 |

√ |

||

|

—— |

—— |

NAK80 (Daido) |

√ |

||

|

Alloy Steel |

4120 |

25CrMo4 / 1.7218 |

SCM420 |

|

Shafts, Gears, Drillers, Chains, Bolts, Nuts, Pins, Suds, Keys, Bites, Crankshafts, Connecting Rods, Came, Couplings etc. |

|

4135 |

34CrMo4 / 1.7220 |

SCM435 |

|

||

|

4130 |

34CrMo4 / 1.7220 |

SCM430 |

√ |

||

|

4140 |

42CrMo4 / 42CrMoS4 / 1.7225 |

SCM440 |

√ |

||

|

4142 |

41CrMo4 / 1.7223 |

SCM440 |

|

||

|

4145H |

—— |

—— |

|

||

|

4330V |

—— |

—— |

|

||

|

4340 |

34CrNiMo6 / 1.6582 |

SNCM439 |

|

||

|

5115 |

16MnCr5 / 16MnCrS5 / 1.7131 |

|

|

||

|

5120 |

20MnCr5 / 20MnCrS5 / 1.7147 |

SMnC420H |

|

||

|

5140 |

41Cr4 / 41CrS4 / 1.7035 |

SCr440 |

√ |

||

|

8620 |

21NiCrMo2 / 1.6523 |

SNCM220 |

|

||

|

8640 |

40NiCrMo2-2 / 1.6546 |

SNCM240 |

|

||

|

—— |

18CrNiMo7-6 / 17CrNiMo6 / 1.6587 |

—— |

|

||

|

9840 |

36CrNiMo4 / 1.6511 |

—— |

|

||

|

E71400 |

41CrAlMo7-10 / 1.8509 |

SACM1 |

|

||

|

—— |

34CrAlNi7 / 1.8550 |

—— |

|

||

|

Bearing Steel |

E52100 |

100Cr6 / 1.3505 |

SUJ2 |

√ |

Bearing, Shafts |

|

—— |

100CrMn6 / 1.3520 |

—— |

|

||

|

—— |

100CrMo7-3 / 1.3536 |

—— |

|

||

|

Spring Steel |

5155 |

55Cr3 / 1.7176 |

SUP9 |

|

Springs |

|

6150 |

51CrV4 / 1.8159 |

SUP10 |

|

||

|

9261 |

60CrSi7 / 1.7108 |

—— |

|

||

|

Carbon Steel |

1010 |

CK10 / C10E / 1.1121 |

S10C |

|

Shafts, Chains, Bolts, Nuts, Pins, Suds, Keys, Bites, Came, Couplings etc. |

|

1020 |

C22 / 1.0402 |

S20C |

√ |

||

|

1040 |

CK40 / C40E / 1.1186 |

S40C |

√ |

||

|

1045 |

CK45 / C45E / 1.1191 |

S45C |

√ |

||

|

1050 |

CK50 / C50E / 1.1206 |

S50C |

√ |

||

|

1055 |

CK55 / C55E / 1.1203 |

S55C |

|

||

|

1064 |

CK60 / C60E / 1.1221 |

S58C |

|

||

|

High Speed Tool Steel |

M2 |

1.3343 |

SKH51 |

√ |

Reamer, |

|

M7 |

1.3348 |

—— |

|

||

|

M42 |

1.3247 |

SKH59 |

√ |

||

|

M35 |

1.3243 |

SKH55 |

√ |

||

|

T1 |

1.3355 |

SKH2 |

|

||

|

T15 |

1.3202 |

—— |

|

||

|

T42 |

1.3207 |

SKH57 |

|